用於5G基站的陶瓷濾波器

5G 時代來臨,Shimadzu 技術有效支援研發製造基地台所需的陶瓷濾波器及導電銀漿

背景簡介

5G 技術是指第五代行動通訊技術,相較於 4G 技術,具有傳輸速率高、延時低、網路荷載量大等特點。另方面,5G 的缺點在於訊號頻帶高,傳輸距離短,穿透能力和覆蓋能力差。因此 5G 需要的基地台數量將遠高於 4G,初期的 5G 架構建設也會集中於架設基地台。例如,中國政府的基礎設施建設政策「新基建」,即是由三大電信營運商主導,2020 年總計安裝了 70 多萬座 5G 基地台。

5G 基地台的天線採整合式設計,訊號處理使用的射頻組件經過大幅修改,天線濾波器的數量也增加。因此,輕量小體積的陶瓷介質濾波器很可能逐步取代現有的金屬腔體濾波器。

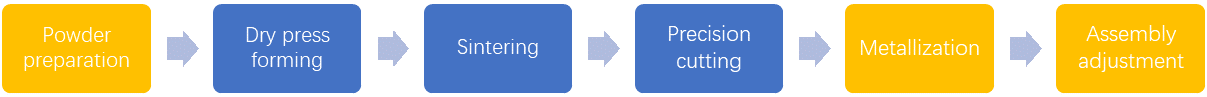

陶瓷介質濾波器的製程:

產業面臨的技術困難及要求

| Ceramic powder formula | Metallization process | Assembly adjustment |

|---|---|---|

| ・Less impurities ・Few defects ・Uniform grain distribution |

・Spray uniformity ・Thickness control ・Conductive silver paste quality |

・Structure and homogeneity of finished products |

支援生產檢驗

Shimadzu has a variety of characterization and testing systems to study ceramic filter production processes.

| Requirements / items in the production process |

Analysis item | Analytical / testing method |

|---|---|---|

| Uniformity of crystalline powder | Crystal phase identification | X-ray Diffraction(XRD) |

| Control and analysis of powder particle size | Particle size distribution measurement | Particle Size Analysis |

| Principal component element analysis | Elemental analysis | Wavelength Dispersive X-ray Fluorescence Spectroscopy(WDXRF) |

| Trace element analysis, trace/impurity analysis | Inductively Coupled Plasma Emission Spectroscopy / Atomic Absorption Spectroscopy(ICP/AA) | |

| Thermodynamic analysis of the effect of additives on the structure of synthetic powders | Thermal analysis | Thermal Analysis(TA) |

| Bending test of piezoelectric ceramic material | Mechanical performance evaluation | Bending Testing |

| Hardness test of piezoelectric ceramic material | Hardness Testing | |

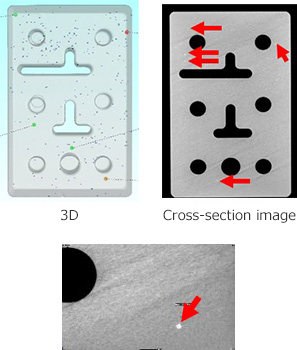

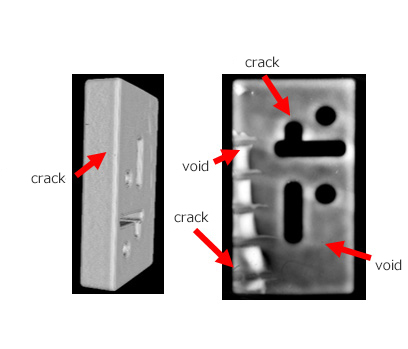

| Observation of gaps, cracks and pores in the ceramic member and on the surface of the finished metal plated layer | Internal structure analysis | X-ray CT |

應用

製造商現在面臨的一個問題是,成品的電氣性能不符合規定,問題起因多半來自燒結和金屬化陶瓷組件表面不平整,以及存在雜質和氣泡。Shimadzu 的 X 光 CT 系統可輕鬆識別陶瓷濾波器中的雜質及缺陷。

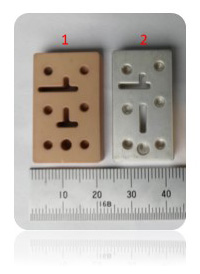

No.1: 陶瓷濾波器

No.2: 金屬化陶瓷濾波器

No.1 樣品

(白點: 汙染物)

No.2 樣品

金屬化步驟中導電銀漿的研究和生產中的測試方法

為確保金屬化過程中,導電銀漿可維持均勻,必須對銀漿的配方、製備過程和製造進行研究及控制。

| Control item | Testing requirements | Testing method |

|---|---|---|

| Physical control of product quality | Solid content | Drying-weighing |

| Viscosity | Rotational viscosity method | |

| Metal powders such as Ag/Al/Cu | Impurity element analysis | Inductively Coupled Plasma (ICP) Emission Spectroscopy |

| Particle size distribution(<500 nm) | Particle Size Analysis | |

| Binders such as glass powder | Influence of Vitrification Temperature and Thermogravimetric Curve of Glass Powder on Conductivity Performance of Electron Slurry | Thermal Analysis |

| Crystallinity of binder | X-ray Diffraction (XRD) | |

| Principal component elemental analysis of glass powder | Energy Dispersive X-ray Spectroscopy | |

| Particle size distribution (1 -10 μm) | Particle Size Analysis | |

| Organic carrier | Test for solvent purity and other low boiling point organic additives | Gas Chromatography(GC-FID) |

| Improvement of Formulation Technology - Study of Action Mechanism | Study on sintering mechanism of functional filler and binder | X-ray Photoelectron Spectroscopy(XPS) |

| UV-VIS Spectroscopy | ||

| Fourier Transform Infrared (FTIR) spectrometer |