Analysis of Non-Metal Inclusions in Steel Using EPMA

Analysis of Non-Metal Inclusions in Steel Using EPMA

Depending on their precipitation state, such as shape, size, and distribution, non-metal inclusions in steel can have a significant effect on the mechanical properties of the steel (toughness, fatigue resistance, and non-aging properties). Investigating fine non-metal inclusions and where they precipitate is important when determining the properties of steel.

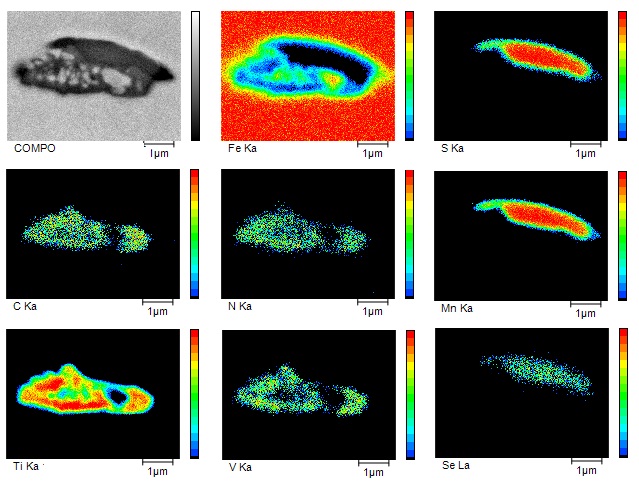

Highly sensitive and high-resolution analysis was conducted by the CeB6-EPMA, which revealed the existence of sulfide non-metal inclusions. Their shapes indicate the coexistence of exogenous inclusions

Element Mapping Images of Non-Metal Inclusions

EPMA-1720 Series Electron Probe Microanalyzers

The electron probe microanalyzer is a non-destructive measurement instrument that irradiates the sample with a finely focused electron beam to reveal the element composition of small areas. It allows the highly sensitive analysis of elements in micron-scale regions on the sample. Simultaneously using submicron-order quantitative analysis and SEM images permits applications to shape inspections. Cause analysis can be performed immediately after foreign matter is discovered.